Downloads

Abstract

The flow analysis systems have become the most growing technological area of chemical analysis because it is the approach that better permeates the automation and notably increases the performance of procedures respecting to higher analytical throughput or lower measurement dispersions. At present most of the literature on new analytical systems are based on some version of flow systems and there are publications specifically dedicated to this topic.

These flow systems, obviously, require a fluid driving system which must have certain characteristics to be adequate. Among them we must mention that the flow must be steady in time, as free as possible of artifacts such as pulsations. It is further desirable that the flow could be adjusted over a wide range, to drive fluid continuously, and be programmed or synchronized to expand the device applicability to different measurement protocols.

Description

Mainly two types of pumping systems are used in flow analyzers: peristaltic pumps and syringe pumps. The first ones consist of a rotor with several rollers pressing a flexible tube, driving the liquid inside through its rotation. They can continuously drive liquid from a reservoir but the shift of a roller to another generates an unwanted variation in the flow that can be registered at the detector as noise. The flow can be adjusted by selecting the flexible tube inner diameter and by controlling the rotational speed of rotor.

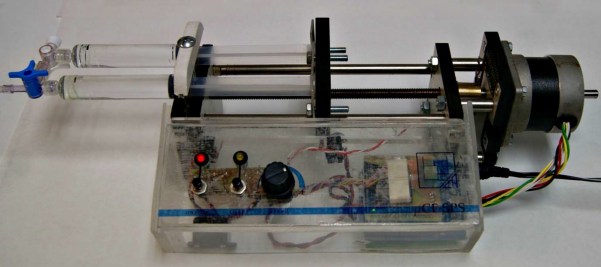

The syringe pumps basically consist of a given volume syringe, whose plunger is driven by a linear motor. The total driven volume is only the volume loaded in the syringe and the flow is virtually free of noise. The flow can be adjusted by selecting the syringe size and the motor speed. This type of pumps can be more compact and lightweight, so they are used for medical applications to continuously dispense controlled doses of drugs.

There are a number of manufacturers selling a wide range of syringe pumps depending on the application and user needs. Therefore there are manual controlled versions, OEM, multichannel, programmable, micro-flow, high pressure, and so; prices ranged from US$ 250 to 5000 and more.

The syringe pump structure is very simple and it can be easily constructed with a minimum of work, some manual ability and a small spending on materials. The electronic control of motor operation allows achieving good levels of precision and accuracy when adjusting the flow and also the micro-controlled operation enables sequence programming and remote/centralized control.

The aim of this project is to illustrate how to make a syringe pump from scratch; which technical considerations must be made at each stage, how to build the hardware, which electronics are needed, how to implement a micro-processor, how and why to communicate with a host computer and how to implement the control software. This project can be useful for chemical/clinical labs without resources or with very specific flow control requirements. It could also serve as a comprehensive building project for engineering students, including mechanical and electronic hardware manufacturing, software programming and communications.

All hardware and software developed is fully accessible on web under Creative Commons Attribution Non-commercial ShareAlike 4.0 license. This means that you can use them on your own derived works, in part or completely, as long as you also adopt the same license and only for non commercial uses. You can find schematics for electrical connections, blueprints for every piece you need, files for 3D print, detailed instructions to build the hardware, bill of matherials and more.

All programming tools used in this project are Free Software.

Demostrative video

The video below shows the syringe pump working from the manual control panel. Also the remote opperation is shown by using the USB connection and the Arduino console.